Are you curious about the differences between Hall Effect and Magnetic Pickup? Look no further! In this article, we will explore the distinctions between these two commonly used technologies. Whether you’re an electronics enthusiast or simply want to expand your knowledge, this is the perfect read for you. Discover how these methods differ in detecting and measuring magnetic fields, and gain a better understanding of their applications in various industries. Prepare to be enlightened as we unravel the intricacies of the Hall Effect and Magnetic Pickup!

Hall Effect

What is the Hall Effect?

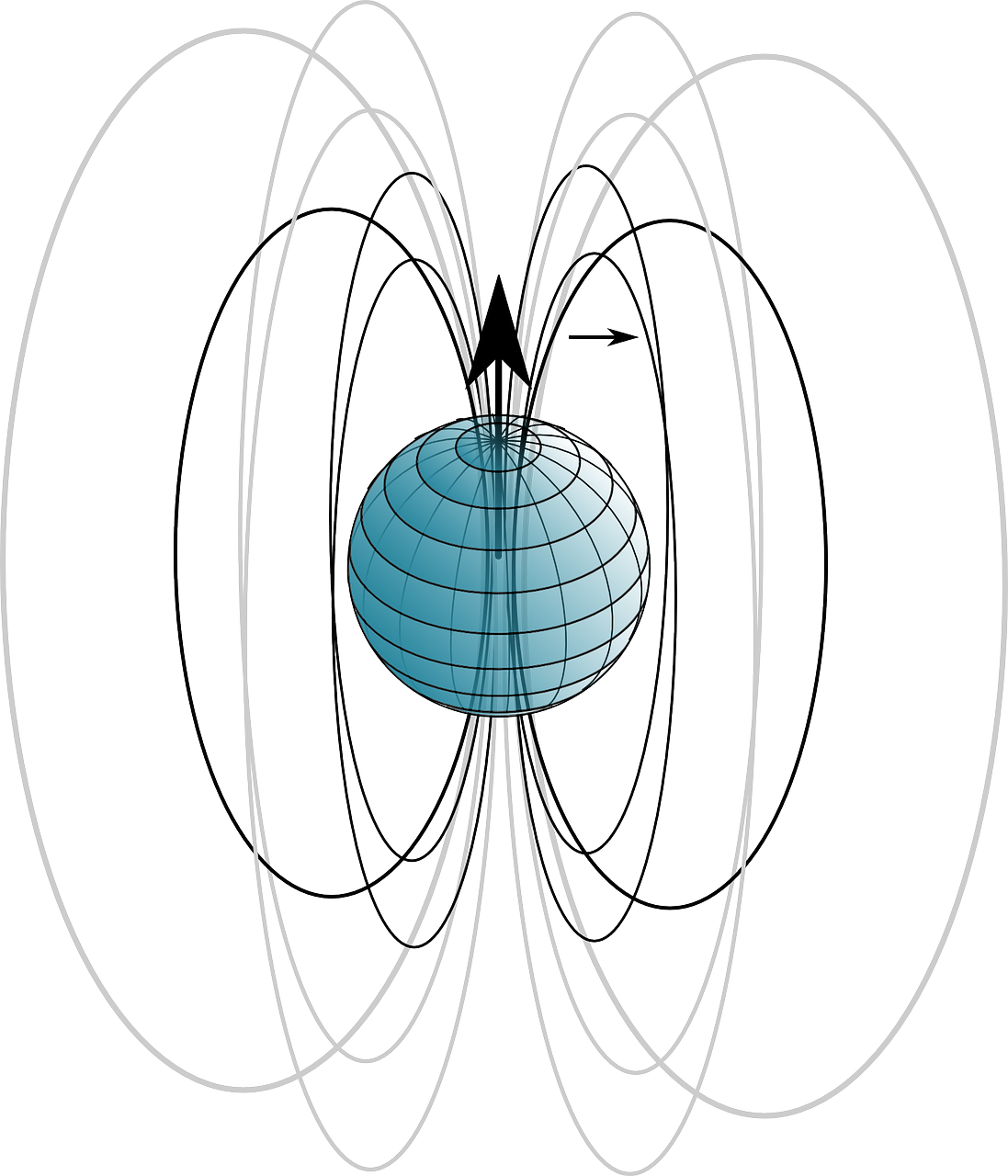

The Hall Effect is a phenomenon in physics that describes the production of a voltage difference (Hall voltage) across an electric conductor when a magnetic field is applied perpendicular to the current flow. It was first discovered by Edwin Hall in 1879. The Hall Effect can be observed in a variety of materials, including metals, semiconductors, and even some liquids.

Principle of the Hall Effect

The principle behind the Hall Effect is based on the Lorentz force, which states that when a charged particle moves through a magnetic field, it experiences a force perpendicular to both the direction of the particle’s motion and the magnetic field. In the case of the Hall Effect, when an electric current flows through a conductive material in the presence of a magnetic field, the Lorentz force causes the charge carriers (usually electrons) to move laterally, resulting in a buildup of charges on one side of the conductor. This charge accumulation creates an electric field, which generates the Hall voltage.

Applications of the Hall Effect

The Hall Effect has a wide range of applications across various industries. Some of the common uses include automotive speed sensing, current sensing, proximity sensing, and position sensing. In the automotive industry, it is used for wheel speed measurement, camshaft position sensing, and throttle position sensing. The Hall Effect is also utilized in electronic compasses, flow rate measurement devices, and magnetic field mapping.

Magnetic Pickup

What is a Magnetic Pickup?

A Magnetic Pickup, also known as a magnetic sensor or magnetic switch, is a type of device that utilizes a magnetic field to detect and measure certain parameters. It commonly consists of a magnetic core, coil, and an output circuit. When a magnetic field is detected, the magnetic pickup produces an electrical signal that can be used for various applications.

Principle of a Magnetic Pickup

The principle behind a Magnetic Pickup is based on the interaction between the magnetic field and the magnetic core/coil arrangement. When a magnetic field is present, it induces a change in the magnetic flux through the coil, which in turn induces an electrical voltage according to Faraday’s law of electromagnetic induction. This voltage is then processed by the output circuit to generate a usable signal.

Applications of a Magnetic Pickup

Magnetic Pickups find application in a range of industries. They are widely used in speed sensing applications, particularly in motor control systems and engines. Magnetic Pickups are commonly employed for RPM sensing in engines, monitoring motor speed in various machinery, and magnetic flow measurement in fluid dynamics. They are also utilized in security systems, automation, robotics, and even musical instruments.

Comparison

Sensing Technique

The Hall Effect relies on the interaction between the magnetic field and the charge carriers in the conductor, while a Magnetic Pickup utilizes the change in magnetic flux to induce an electrical signal.

Working Principle

The Hall Effect uses the Lorentz force to generate a Hall voltage, while a Magnetic Pickup employs Faraday’s law of electromagnetic induction to detect and measure magnetic fields.

Output Signal

The Hall Effect produces a voltage difference (Hall voltage), while a Magnetic Pickup generates an electrical signal that can be voltage, current, or a digital output depending on the application.

Sensitivity

The sensitivity of the Hall Effect sensors can be adjusted by varying the current and the strength of the magnetic field, whereas the sensitivity of a Magnetic Pickup is determined by the number of turns in the coil and the strength of the magnetic field it is exposed to.

Frequency Response

The Hall Effect sensors generally have a wide frequency response, allowing them to detect changes in the magnetic field at high frequencies. On the other hand, the frequency response of a Magnetic Pickup depends on the specific design and application requirements.

Advantages of the Hall Effect

Contactless Operation

One of the major advantages of the Hall Effect is its contactless operation. It can sense and measure magnetic fields without any physical contact, reducing the wear and tear of the sensor and the need for maintenance.

High Reliability

Hall Effect sensors are known for their high reliability. They are not affected by factors like vibration, dust, or moisture, making them suitable for harsh environments and long-term use.

Wide Temperature Range

Hall Effect sensors can operate effectively in a wide temperature range, from extremely low temperatures to high temperatures, making them suitable for applications in various industries and environments.

Disadvantages of the Hall Effect

External Magnetic Field

In some cases, the presence of external magnetic fields can interfere with the accuracy of Hall Effect sensors, leading to potential measurement errors. Proper shielding and isolation techniques are required to minimize this effect.

Limited Output Signal

While the Hall Effect sensors provide a voltage difference as the output signal, the magnitude of the voltage is relatively small. This limitation can impact the signal-to-noise ratio and may require additional amplification or signal conditioning.

Expensive

Compared to other sensing techniques, Hall Effect sensors can be relatively expensive. The cost of the sensor, along with the associated circuitry, may make it less viable for certain applications with strict budget constraints.

Advantages of Magnetic Pickup

Low Cost

Magnetic Pickups are generally more cost-effective compared to Hall Effect sensors. They offer a simpler design and can be manufactured at a lower cost, making them a popular choice for applications with budget limitations.

Simple Design

Magnetic Pickups have a simple design with fewer components, making them easy to integrate and use. Their straightforward operation allows for quick and hassle-free installation.

Robustness

Magnetic Pickups are known for their robustness and durability. They can withstand harsh environmental conditions, vibrations, and mechanical impacts, ensuring long-term reliable performance.

Disadvantages of Magnetic Pickup

Friction and Wear

Magnetic Pickups that require physical contact with a rotating shaft or gear may experience friction and wear over time. This can lead to accuracy issues and the eventual need for maintenance or replacement.

Sensitive to Vibration

Magnetic Pickups can be sensitive to vibrations, especially in applications where mechanical components are prone to vibrations. Adequate measures need to be taken to minimize the impact of vibrations on the sensor’s performance.

Limited Temperature Range

The temperature range in which Magnetic Pickups can operate optimally is relatively narrower compared to Hall Effect sensors. They may not be suitable for extreme temperature conditions without additional temperature compensation measures.

Suitable Applications for Hall Effect

Automotive Speed Sensing

Hall Effect sensors are widely used in automotive speed sensing applications, such as wheel speed measurement and transmission speed sensing. Their contactless operation and high reliability make them ideal for these applications.

Current Sensing

The Hall Effect is commonly utilized for measuring current in various electronic devices and systems. They can accurately detect the presence and magnitude of current flow, making them suitable for current sensing applications.

Proximity Sensing

The Hall Effect’s ability to detect magnetic fields makes it an excellent choice for proximity sensing. It can be used in proximity switches, door and window position sensing, and other applications that require non-contact detection.

Suitable Applications for Magnetic Pickup

Motor Speed Sensing

Magnetic Pickups are frequently used for motor speed sensing in various machinery and equipment. They provide a cost-effective solution for monitoring the rotational speed of motors and ensuring optimal performance.

RPM Sensing in Engines

In automotive and industrial engines, Magnetic Pickups are commonly employed for RPM sensing. They allow for precise measurement of engine speed, enabling better control and monitoring of engine performance.

Magnetic Flow Measurement

Magnetic Pickups are extensively used in magnetic flow meters for measuring the flow rate of conductive liquids, such as water or oil. They provide an accurate and reliable method for monitoring fluid dynamics.

Conclusion

Both the Hall Effect and Magnetic Pickup are valuable sensing techniques with their own distinct advantages and disadvantages. The Hall Effect offers contactless operation, high reliability, and a wide temperature range, making it suitable for automotive speed sensing, current sensing, and proximity sensing applications. On the other hand, Magnetic Pickups provide a low-cost solution with a simple design and robustness, making them ideal for motor speed sensing, RPM sensing in engines, and magnetic flow measurement. Choosing between the two ultimately depends on the specific requirements and constraints of the application.