Are you a diesel enthusiast eager to learn about the differences between Cummins VE Pump and P-pump? Look no further! In this article, we’ll provide a comprehensive comparison of these two types of fuel injection systems for Cummins engines. Get ready to delve into the world of diesel engines as we explore the features and benefits of both the Cummins VE Pump and the P-pump, laying out the key factors that differentiate these fuel injection systems. Whether you’re a seasoned truck driver or a diesel engine aficionado, this article is designed to provide you with valuable insights into the world of Cummins engines. So sit back, relax, and let’s explore the Cummins VE Pump vs. P-pump showdown!

Introduction

Welcome to this comprehensive comparison article on the Cummins VE Pump and the P-pump. If you’re an automotive enthusiast or a truck owner, you’ve probably come across these two types of fuel injection systems. In this article, we will dive deep into their design, fuel delivery systems, injector control, performance, fuel economy, maintenance, aftermarket support, and cost. By the end of this read, you’ll have a clear understanding of the differences and benefits of both the Cummins VE Pump and the P-pump.

Overview

Let’s start with a brief introduction to both the Cummins VE pump and the P-pump.

Brief introduction to Cummins VE pump and P-pump

The Cummins VE pump, also known as the Cummins P7100, is a mechanical inline fuel injection system commonly found in Cummins-powered vehicles produced from 1989 to 1998. It features a rotary distributor pump design and provides precise fuel delivery to each cylinder of the engine.

On the other hand, the P-pump, also known as the Bosch P7100, is a mechanical inline fuel injection system that was primarily used in Cummins-powered vehicles from 1994 to 1998. It is renowned for its mechanical simplicity and reliability, making it a popular choice among truck enthusiasts and diesel performance enthusiasts alike.

Design

Now, let’s explore the design of both the Cummins VE Pump and the P-pump.

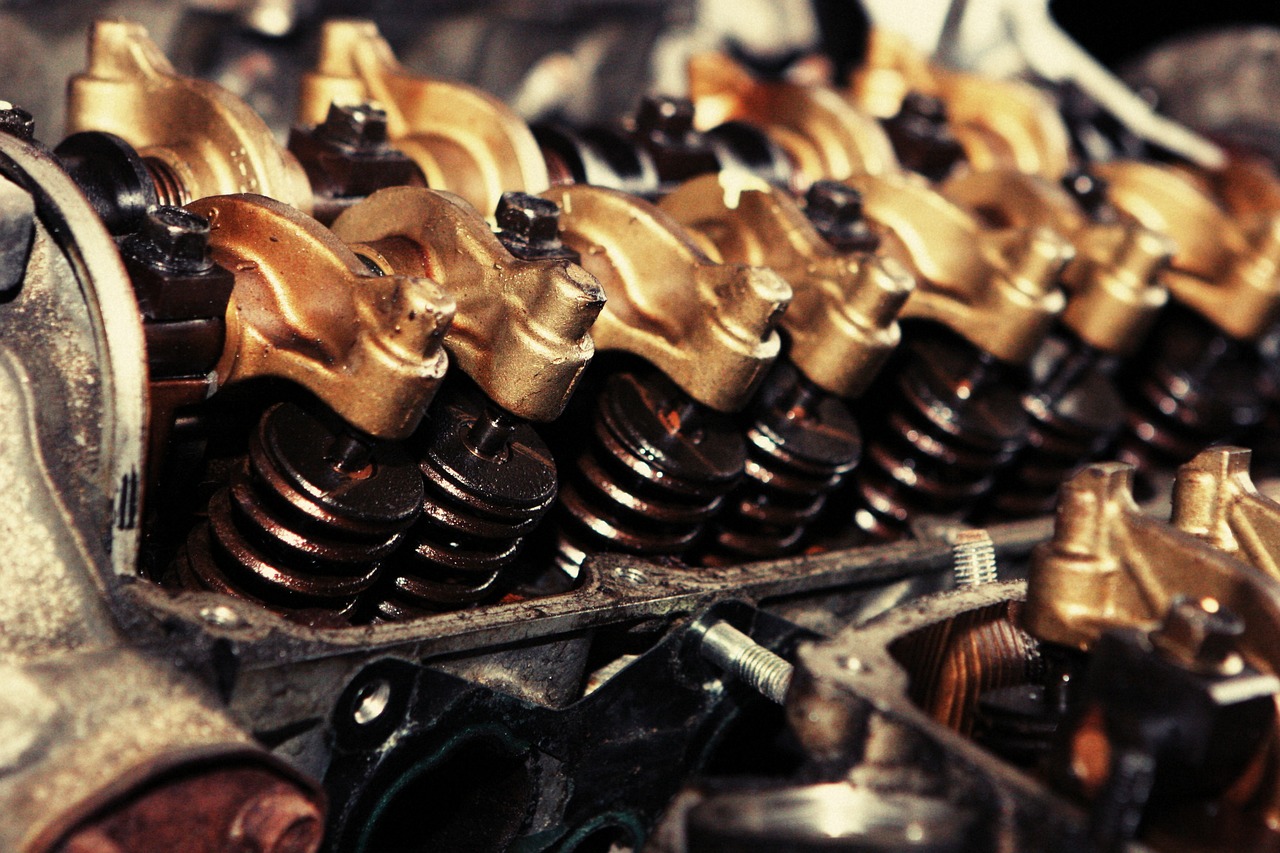

Cummins VE Pump Design

The Cummins VE pump is a mechanical rotary distributor pump that operates through a rack and pinion system. It uses an eccentric camshaft to generate high-pressure fuel to distribute to each individual injector. The rotary design ensures precise fuel metering and timing for optimal engine performance. However, due to its design, it may have limitations when it comes to delivering fuel at extremely high pressures.

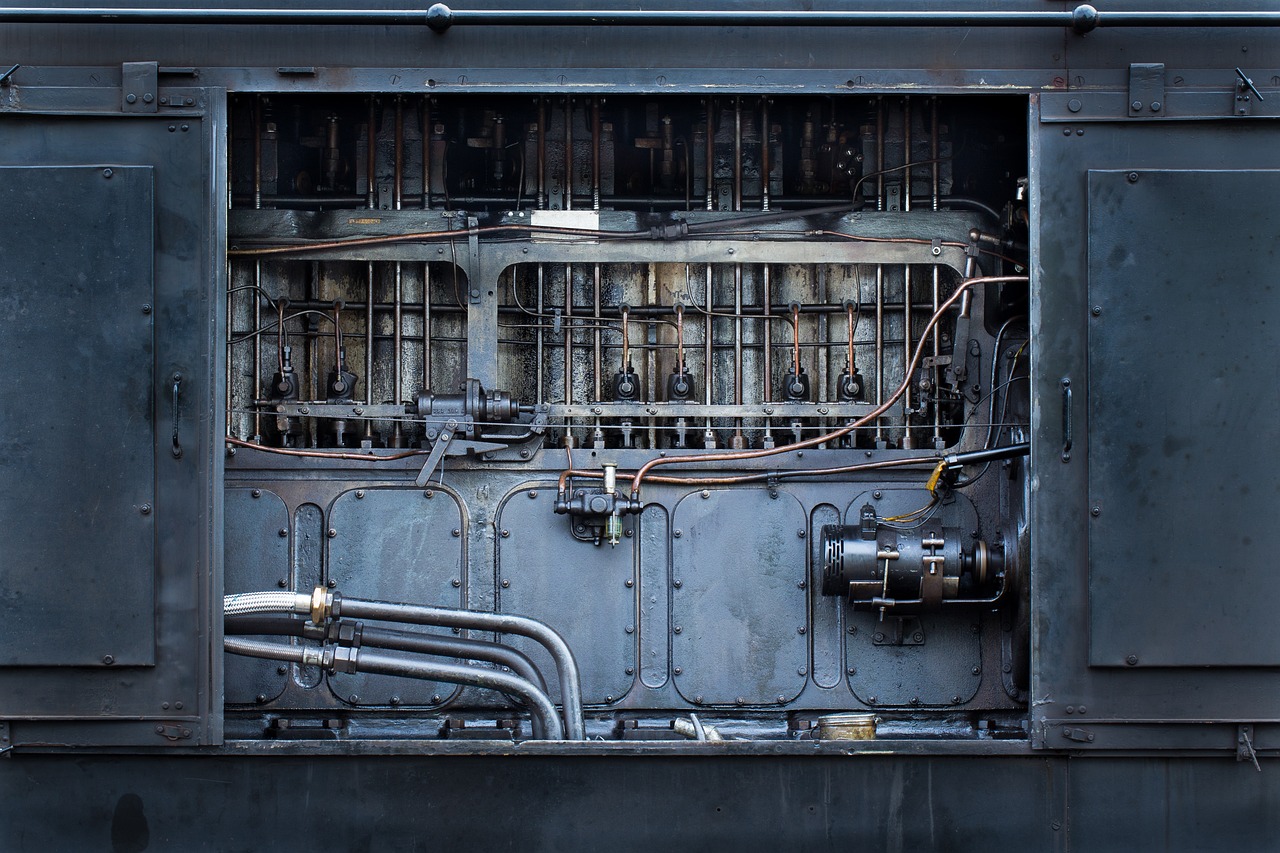

P-pump Design

The P-pump, also a mechanical inline fuel injection system, is known for its robust design and simplicity. It features individual plungers and barrels for each injector, allowing for precise control of fuel delivery. The camshaft-driven plunger and barrel design provide excellent fuel pressure and enable the P-pump to handle even the most demanding performance applications. Its design makes it a popular choice for those seeking performance enhancements and modifications.

Fuel Delivery System

Next, let’s take a closer look at the fuel delivery systems of the Cummins VE Pump and the P-pump.

Cummins VE Pump Fuel Delivery System

The Cummins VE pump utilizes a mechanical system that pressurizes fuel and delivers it to the injectors. The fuel is drawn from the fuel tank by a lift pump, which then sends it to the VE pump. Once inside the VE pump, the fuel is pressurized and distributed to each individual injector in the correct firing order. This system is known for its simplicity and reliability.

P-pump Fuel Delivery System

The P-pump also employs a mechanical fuel delivery system. Similar to the VE pump, it utilizes a lift pump to draw fuel from the tank. This fuel is then sent to the P-pump, where it undergoes pressurization. The P-pump’s design allows for precise control of fuel delivery to each injector, ensuring optimal combustion and performance.

Injector Control

Moving on, let’s examine the injector control mechanisms of the Cummins VE Pump and the P-pump.

Cummins VE Pump Injector Control

The Cummins VE pump relies on a mechanical control system that determines the timing and duration of fuel injection. The position and movement of the VE pump’s internal components regulate the amount of fuel injected into each cylinder. While this design offers straightforward operation and reliability, it may have limitations when it comes to fine-tuning injection timing for specific performance needs.

P-pump Injector Control

The P-pump’s injector control system provides precise control over the timing and duration of fuel injection. The camshaft-driven plunger and barrel design allow for maximum versatility when it comes to adjusting injection timing and fuel delivery. This level of control makes the P-pump a popular choice for those seeking performance enhancements and custom tuning.

Performance

Now, let’s evaluate the performance characteristics of both the Cummins VE Pump and the P-pump.

Cummins VE Pump Performance

The Cummins VE pump delivers reliable and consistent performance across a wide range of engine loads. Its rotary design ensures precise fuel metering and timing, resulting in efficient combustion. However, due to its lower maximum fuel delivery capabilities compared to the P-pump, the VE pump may have limitations when it comes to extreme performance upgrades and modifications.

P-pump Performance

The P-pump is highly regarded for its performance potential. Its ability to handle high fuel pressures, combined with its precise injector control, makes it a favorite among performance enthusiasts. Whether you’re looking for increased horsepower, torque, or improved throttle response, the P-pump can be modified and tuned to meet your specific needs.

Fuel Economy

Considering fuel efficiency? Let’s explore the fuel economy of both the Cummins VE Pump and the P-pump.

Cummins VE Pump Fuel Economy

The Cummins VE pump is known for its efficient fuel delivery and reliable performance, which translates to good fuel economy. Its mechanical design ensures precise metering of fuel, optimizing combustion and minimizing fuel wastage. With proper maintenance and driving habits, the VE pump-equipped vehicles can achieve respectable fuel efficiency figures.

P-pump Fuel Economy

The P-pump, similar to the VE pump, offers respectable fuel economy figures when properly maintained and driven. While its performance potential may tempt some owners to push the limits, keeping the P-pump within efficient operating parameters will result in good fuel efficiency. However, it’s important to note that aggressive modifications and performance upgrades may impact fuel economy negatively.

Maintenance

Maintenance is a crucial aspect to consider, so let’s compare the maintenance requirements of the Cummins VE Pump and the P-pump.

Cummins VE Pump Maintenance

The Cummins VE pump is known for its simplicity and ease of maintenance. Routine maintenance includes regular fuel filter changes, lubrication, and periodic timing adjustments. With proper care and maintenance, the VE pump can provide reliable service for many years.

P-pump Maintenance

Similarly, the P-pump is relatively easy to maintain. Routine maintenance, such as regular fuel filter changes, lubrication, and occasional timing adjustments, can keep the P-pump in top condition. However, as modifications and performance enhancements increase, additional maintenance may be required to ensure optimal performance and longevity.

Aftermarket Support

Now, let’s discuss the aftermarket support available for both the Cummins VE Pump and the P-pump.

Cummins VE Pump Aftermarket Support

The Cummins VE pump enjoys widespread aftermarket support, considering its popularity and the number of vehicles equipped with this fuel injection system. Upgrading components, modifying fuel delivery, and tuning for performance enhancements are all possible with the available aftermarket support for the VE pump.

P-pump Aftermarket Support

The P-pump also benefits from a strong aftermarket support network. Enthusiasts looking to increase performance, modify fuel delivery, or fine-tune their engine have plenty of options. From modified plunger and barrel combinations to custom tuning, the P-pump aftermarket support offers a wide range of upgrades to meet the needs of every enthusiast.

Cost

Lastly, let’s compare the costs associated with the Cummins VE Pump and the P-pump.

Cummins VE Pump Cost

The Cummins VE pump’s simplicity and widespread availability make it a more affordable option compared to the P-pump. The VE pump’s cost can vary depending on factors such as condition, availability, and any additional components included in the purchase.

P-pump Cost

The P-pump, being renowned for its performance potential, tends to come at a higher price compared to the Cummins VE pump. The demand for P-pumps in the performance sector often leads to increased prices for used units. Additionally, performance-oriented modifications and enhancements may incur additional costs beyond the initial purchase of the P-pump.

In conclusion, both the Cummins VE pump and the P-pump offer their unique advantages and considerations. Whether you prioritize simplicity, reliability, performance, or aftermarket support, understanding the different characteristics of these fuel injection systems will help you make an informed decision for your specific needs.