Looking for the best header gaskets for your Small Block Chevy (SBC) engine? Look no further! In this article, we will explore some top-notch options that will ensure a tight seal and optimal performance for your SBC. Whether you’re a DIY enthusiast or a seasoned mechanic, finding the right header gasket is crucial for preventing leaks and maximizing your engine’s power output. So, let’s dive right in and discover the best header gaskets available for your SBC!

1. Importance of Header Gaskets for SBC

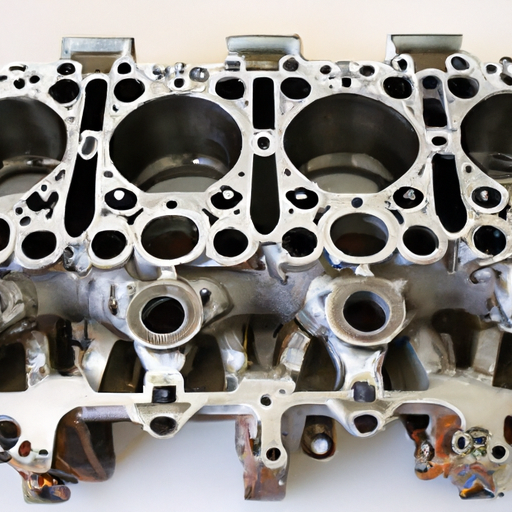

1.1 Minimizing Exhaust Leaks

Header gaskets play a crucial role in minimizing exhaust leaks in Small Block Chevy (SBC) engines. These high-performance engines generate a significant amount of heat and pressure, and without proper sealing, exhaust gases can escape from the connection between the cylinder head and the exhaust manifold or headers. Exhaust leaks not only result in a loss of engine power but can also lead to harmful gases entering the passenger compartment. The use of high-quality header gaskets ensures a tight and secure seal, preventing any leaks and providing optimal performance.

1.2 Improving Engine Performance

In addition to minimizing exhaust leaks, header gaskets also contribute to improving engine performance in SBC engines. By providing a proper seal, these gaskets help in maintaining backpressure, which is essential for optimizing the flow of exhaust gases from the cylinders. Improved exhaust flow ensures efficient combustion, resulting in enhanced horsepower and torque. Furthermore, header gaskets help in reducing the overall weight of the exhaust system, leading to improved acceleration and fuel efficiency. These benefits make header gaskets an essential component for anyone seeking to maximize the performance of their SBC engine.

1.3 Extending Gasket Lifespan

Another key importance of header gaskets for SBC engines is their ability to extend the lifespan of the gaskets themselves. Due to the high temperatures and pressures involved, header gaskets are susceptible to wear and deterioration over time. However, by using high-quality gaskets, properly installed and maintained, the risk of premature failure can be significantly reduced. This not only saves you from the hassle and cost of frequent gasket replacements but also ensures consistent performance from your SBC engine. Investing in durable and reliable header gaskets is, therefore, crucial for the longevity and reliability of your engine.

2. Different Types of Header Gaskets

When it comes to choosing header gaskets for your SBC engine, you’ll come across various types, each offering unique features and benefits. Let’s take a closer look at the different options available:

2.1 Solid Copper Gaskets

Solid copper gaskets are popular amongst performance enthusiasts looking for reliable sealing and durability. These gaskets are made entirely of copper, which provides excellent heat resistance and allows for better thermal conductivity. The malleability of copper ensures a tight seal, even under extreme conditions, preventing exhaust leaks effectively. Solid copper gaskets are especially suitable for engines with high compression ratios or forced induction, where reliable sealing is critical. However, it’s worth noting that solid copper gaskets require careful installation and may need periodic retorquing to maintain the seal.

2.2 Composite Gaskets

Composite gaskets are a common choice for SBC engines due to their affordability and versatility. These gaskets are usually made from a combination of materials, such as graphite or reinforced fiber, bonded with a rubber or silicone coating. Composite gaskets offer excellent sealing properties, thanks to the compressibility and flexibility of the materials used. They can withstand high temperatures and pressures, making them suitable for most SBC applications. However, composite gaskets may not offer the same level of durability as solid copper gaskets and may require more frequent replacement under extreme conditions.

2.3 Steel Core Laminate Gaskets

Steel core laminate gaskets are designed to provide a robust and reliable seal for SBC engines. These gaskets feature multiple layers of steel with a rubber or silicone coating on both sides. The steel core adds strength and rigidity to the gasket, while the coating ensures excellent sealing properties. Steel core laminate gaskets offer superior resistance to heat, chemicals, and fluids, making them a suitable choice for demanding applications. However, due to their construction, these gaskets can be less forgiving when it comes to surface irregularities, requiring careful installation and surface preparation.

2.4 Multi-Layered Steel Gaskets

Multi-layered steel (MLS) gaskets are known for their exceptional durability and sealing performance. These gaskets consist of multiple thin layers of steel, often coated with a high-temperature elastomer or polymer. The layers are usually embossed or folded, creating a strong and reliable seal. MLS gaskets excel in providing excellent conformity to irregular surfaces and withstand extreme conditions without compromising the seal. They are commonly used in high-performance and racing applications, where cylinder pressures and temperatures are significantly higher. However, due to their construction and performance, MLS gaskets are generally more expensive than other options.

2.5 Graphite Gaskets

Graphite gaskets offer a balance between affordability and performance, making them a popular choice for many SBC engine owners. These gaskets are typically constructed using multiple layers of graphite, sandwiching a metal core or wire mesh reinforcement. Graphite gaskets provide excellent heat resistance and conformability, allowing them to effectively seal irregular surfaces. They also exhibit good chemical resistance, making them suitable for a wide range of applications. However, graphite gaskets may not offer the same level of durability as some other options, and they may require occasional retorquing to maintain a tight seal in high-performance applications.

3. Factors to Consider When Choosing Header Gaskets

When selecting header gaskets for your SBC engine, several factors should be taken into consideration to ensure optimal performance and longevity. Let’s explore these factors in detail:

3.1 Engine Compatibility

Before purchasing header gaskets, it’s crucial to verify their compatibility with your specific SBC engine. Different engines may have variations in cylinder head designs, exhaust port sizes, and bolt patterns. Ensuring that the gaskets are designed to fit your engine’s specifications will help avoid installation issues and ensure a proper and secure seal.

3.2 Performance Needs

Consider your performance needs when choosing header gaskets. If you have a highly modified or high-performance SBC engine, gaskets with superior sealing properties and durability may be necessary. On the other hand, if your engine is stock or lightly modified, gaskets that provide a good balance of performance and affordability may be more suitable.

3.3 Header Material

The material of the headers or exhaust manifold used in your SBC engine can also influence your choice of gaskets. Different materials, such as cast iron, stainless steel, or ceramic-coated steel, have varying thermal expansion rates and surface finishes. It’s important to select gaskets that are compatible with the header material to ensure proper sealing and prevent potential issues like leakage or gasket blowouts.

3.4 Gasket Material

Consider the material composition of the gaskets and their suitability for your specific application. Each gasket material offers different strengths in terms of heat resistance, sealing properties, and durability. Evaluate the advantages and limitations of different materials, such as copper, composite, steel core laminate, multi-layered steel, and graphite, to choose the one that best suits your needs.

3.5 Installation Difficulty

Take into account the ease of installation when selecting header gaskets. Some gasket materials, such as solid copper or steel core laminate, may require more precise installation techniques or additional steps, like surface preparation or the use of sealant. If you’re unfamiliar with advanced installation procedures, opting for gaskets that are easier to install, such as composite or graphite gaskets, might be a better choice.

3.6 Budget

Consider your budget when choosing header gaskets. Gaskets come in a range of prices, depending on their material, construction, and performance capabilities. It’s essential to find the right balance between affordability and quality, ensuring that you invest in gaskets that provide reliable sealing and durability without exceeding your budget.

4. Top 5 Header Gaskets for SBC

To help you narrow down your options, here are five top header gasket brands known for their quality and performance in SBC engines:

4.1 Brand A Header Gasket

Brand A offers a wide range of header gaskets specifically designed for SBC engines. Their gaskets showcase a solid copper construction, providing excellent heat resistance and sealing capabilities. Brand A gaskets are known for their durability and reliability, making them a popular choice among performance enthusiasts.

4.2 Brand B Header Gasket

Brand B’s header gaskets are renowned for their composite construction, combining graphite or reinforced fiber materials with a silicone or rubber coating. These gaskets offer excellent durability and sealing properties, making them suitable for a variety of SBC applications. Brand B’s gaskets also provide good value for money, offering a balance between performance and affordability.

4.3 Brand C Header Gasket

Brand C specializes in steel core laminate gaskets, designed to deliver a secure and reliable seal for SBC engines. Their gaskets feature multiple layers of steel with a rubber or silicone coating, providing excellent resistance to heat, chemicals, and fluids. Brand C gaskets are known for their durability, making them an ideal choice for demanding applications.

4.4 Brand D Header Gasket

Brand D’s multi-layered steel (MLS) gaskets are highly regarded for their exceptional sealing performance and durability. These gaskets consist of multiple thin steel layers with a high-temperature elastomer or polymer coating, ensuring a reliable and robust seal even under extreme conditions. Brand D’s MLS gaskets are favored by racing enthusiasts and those seeking maximum performance from their SBC engines.

4.5 Brand E Header Gasket

Brand E offers graphite gaskets that strike a balance between performance and affordability. Their gaskets feature multiple layers of graphite with a metal core or wire mesh reinforcement, providing good heat resistance and conformability. Brand E’s graphite gaskets are suitable for a wide range of SBC applications and offer reliable sealing at a reasonable price point.

5. Pros and Cons of Solid Copper Gaskets

Solid copper gaskets are a popular choice for SBC engines due to their unique characteristics. Let’s explore the pros and cons of using solid copper gaskets:

5.1 Pros

- Excellent heat resistance: Copper is known for its exceptional thermal conductivity and heat resistance, making solid copper gaskets ideal for high-temperature applications.

- Reliable sealing properties: Solid copper gaskets offer excellent malleability, allowing them to conform to irregular surfaces and provide a tight seal, minimizing the risk of exhaust leaks.

- Durability: Copper gaskets have good resistance to heat, chemicals, and fluids, ensuring long-lasting performance and minimizing the need for frequent replacements.

5.2 Cons

- Installation challenges: Solid copper gaskets require careful installation due to their malleability. This includes proper surface preparation, torque specifications, and potentially periodic retorquing to maintain the seal.

- Cost: Solid copper gaskets tend to be more expensive compared to other gasket options, primarily due to the material’s cost and manufacturing complexity.

6. Pros and Cons of Composite Gaskets

Composite gaskets are widely used in SBC engines for their versatility and affordability. Let’s examine the pros and cons of using composite gaskets:

6.1 Pros

- Affordability: Composite gaskets are generally more budget-friendly compared to some other gasket options, making them an attractive choice for cost-conscious engine owners.

- Good sealing properties: The compressibility and flexibility of composite materials, such as graphite or reinforced fiber, allow them to effectively seal irregular surfaces, preventing exhaust leaks.

- Versatility: Composite gaskets are suitable for a variety of SBC applications and can withstand high temperatures and pressures, ensuring reliable performance.

6.2 Cons

- Durability limitations: While composite gaskets offer good sealing properties, they may not possess the same level of durability as other materials like solid copper or multi-layered steel. Under extreme conditions, composite gaskets may require more frequent replacements.

- Material limitations: Composite gaskets may have limitations when it comes to resistance to certain chemicals or fluids. It’s important to ensure compatibility with your specific application requirements.

7. Pros and Cons of Steel Core Laminate Gaskets

Steel core laminate gaskets provide a robust and reliable seal for SBC engines. Let’s explore the advantages and limitations of using steel core laminate gaskets:

7.1 Pros

- Reliability: Steel core laminate gaskets offer excellent resistance to heat, chemicals, and fluids, ensuring a secure seal under demanding conditions.

- Strength and rigidity: The steel core adds strength and rigidity to the gaskets, enhancing their ability to maintain a consistent seal, even under high pressures.

- Compatibility with irregular surfaces: Steel core laminate gaskets can accommodate slight surface irregularities, providing a reliable seal despite minor imperfections.

7.2 Cons

- Installation complexity: Due to their construction, steel core laminate gaskets may require more precise installation techniques, including proper surface preparation, torque specifications, and potentially the use of sealant.

- Surface requirement: Steel core laminate gaskets are less forgiving when it comes to surface irregularities. A smooth mating surface is crucial for achieving a proper seal.

8. Pros and Cons of Multi-Layered Steel Gaskets

Multi-layered steel (MLS) gaskets are known for their exceptional durability and sealing performance. Let’s discuss the pros and cons of using MLS gaskets:

8.1 Pros

- Superior sealing performance: MLS gaskets provide excellent conformity to irregular surfaces, ensuring a reliable seal even under high pressures and temperatures.

- Excellent durability: MLS gaskets are highly resistant to heat, chemicals, and fluids, making them ideal for demanding applications where reliability is paramount.

- Maintenance-free: MLS gaskets generally do not require retorquing or frequent replacements, thanks to their robust construction and sealing capabilities.

8.2 Cons

- Higher cost: The construction and performance benefits of MLS gaskets come at a higher price compared to other gasket options. They may be more expensive initially, but their durability can result in longer-term cost savings.

9. Pros and Cons of Graphite Gaskets

Graphite gaskets offer a balance between performance and affordability. Let’s examine the pros and cons of using graphite gaskets:

9.1 Pros

- Good heat resistance: Graphite gaskets exhibit good resistance to high temperatures, making them suitable for use in SBC engines with moderate to high thermal demands.

- Conformability: The layers of graphite in these gaskets allow them to conform to irregular surfaces, ensuring a tight and secure seal, even in slightly imperfect conditions.

- Affordability: Graphite gaskets offer reliable sealing capabilities at a more affordable price point, making them a popular choice for those on a budget.

9.2 Cons

- Durability limitations: While graphite gaskets provide reliable sealing, their durability may not match that of some other materials like solid copper or multi-layered steel. Under extreme conditions, they may require occasional retorquing or more frequent replacements.

- Compatibility considerations: Certain chemicals or fluids may adversely affect the performance of graphite gaskets. It’s important to evaluate the gasket’s compatibility with your specific application requirements.

10. Tips for Installing Header Gaskets

Installing header gaskets correctly is essential for ensuring optimal performance and preventing exhaust leaks. Here are some tips to keep in mind during the installation process:

10.1 Proper Surface Preparation

Ensure the mating surfaces of the cylinder head and the exhaust manifold or headers are clean, smooth, and free from any debris or old gasket material. Use a gasket scraper or a wire brush to remove any residue and ensure a proper surface for the gasket to seal against.

10.2 Correct Torque Specifications

Refer to the manufacturer’s instructions or specifications to determine the correct torque settings for your specific header gaskets. Use a torque wrench to tighten the bolts in a consistent and proper manner, following the recommended sequence if provided.

10.3 Using Copper Anti-Seize Compound

To prevent the gasket from sticking to the mating surfaces or causing damage during future disassembly, consider applying a thin layer of copper anti-seize compound to both sides of the gasket. This will help with easier removal and reinstallation in case of maintenance or repairs.

By following these tips, you can ensure a successful installation and maximize the performance and lifespan of your header gaskets in your SBC engine.

In conclusion, header gaskets are vital components for SBC engines, minimizing exhaust leaks, improving engine performance, and extending the gasket lifespan. Understanding the different types of gaskets available, considering factors such as engine compatibility, performance needs, header and gasket materials, installation difficulty, and budget, will help you make an informed decision. Whether you choose solid copper, composite, steel core laminate, multi-layered steel, or graphite gaskets, each option has its own set of pros and cons. Finally, following proper installation techniques, including surface preparation, correct torque specifications, and, if necessary, the use of copper anti-seize compound, will ensure a tight and secure seal and optimal performance from your SBC engine.